TIG is part of our welding solutions offering and is often complementary to EB Welding. We are a welding specialist committed to the highest weld quality – meeting the needs of complex projects in the aerospace, defence, nuclear, medical equipment, and with approvals from the most demanding OEMs.

In-house we have X-ray, Penetrant, Vacuum leak and Pressure testing plus a material section and test laboratory.

Our accredited staff and a trading history going back to 1966 tell of our experience.

Your welding solutions come with EBP professional advice to help you choose the best method for your project. Design support and DFM is available, plus technical support via membership of TWI (The Welding Institute).

What Is Arc Welding?

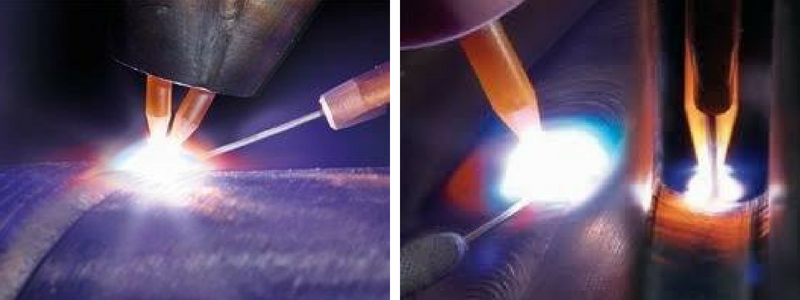

Arc welding uses an electrode to create an electric arc that generates the heat required to melt the material at the joint. Filler wire is used to add material to the joint on all but the thinnest materials

Arc welding is extremely versatile, EBP uses Gas Tungsten Arc Welding (GTAW), or Tungsten Inert Gas (TIG) welding, a precision form of arc welding using non-consumable tungsten electrodes and an inert gas (usually helium or argon) to shield the weld area from oxidation.

We have computer-controlled welding machines, which feedback systems for purge gas flow and filler wire feed rate.

Our equipment can also be used for metal build-up by applying layers of high corrosion or high wear resistant materials to a low-cost base material, or for component salvage

Flexible Welding Solutions

The combination of EBW and TIG provides flexible solutions such as the example attached

![]()