The Key Benefits of Electron Beam

- Minimal Distortion – welds finish machined parts

- Welds difficult and dissimilar materials

- Exceptional Quality and Repeatability

- High Weld Speeds

- Deep narrow welds of close to Parent Metal strength

Producing savings in cost, weight, lead time, size and inventory.

EBW is a machine controlled process, with welding carried out in a vacuum with no filler material, resulting in exceptional weld quality and repeatability.

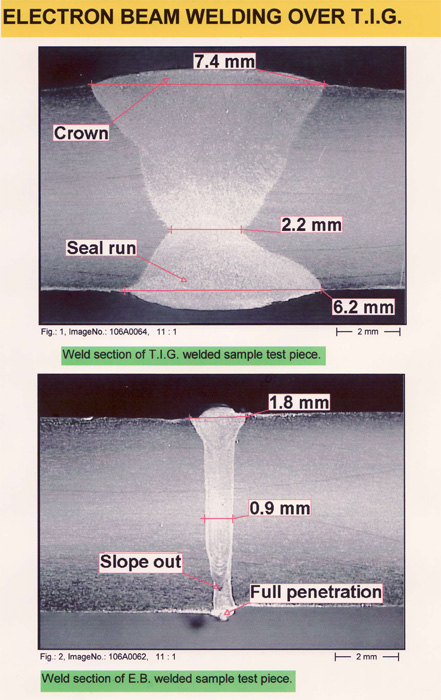

Weld speeds are typically 1-2 metres/min and result in deep, narrow welds requiring less than 5% of the heat input needed for a comparable depth TIG weld.

Distortion low enough to weld finish ground gears

See a range of industrial applications in here

How The Process Works

Click below to see a short video explaining how the process works.

EB WELDING FAQs

What is the difference between EB & Arc welding?

Arc welding melts metal by applying heat via an arc or plasma faster than it can conduct away until a molten pool is achieved. On thin materials, <2.0mm, the heat source is moved along the joint leaving the melted metal to fuse to. For thicker materials, a “vee” 90° is needed to add filler metal, which is added to the molten pool to fill the “vee”.

This is a slow process, with weld speeds of 20-30mm/min, and applies a lot of heat to the top surface, resulting in distortion as the welded metal cools and shrinks.

E B welding uses a focused beam of electrons, which can focus 4KW into a spot of 0.5mm diameter. This instantly melts the metal to a vapour hole surrounded by liquid. Deep welds can be produced at high speeds.

Total heat input for EB welding is less than 5% of that required by Arc welding, resulting in minimal distortion.

Is EB welding equipment expensive and if so how does it compete with conventional welding?

EB equipment is expensive; £300,000 to £2,000,000 is typical, subject to the size of machine. There are many areas where the advantages justify the cost.

- Repeatable weld quality; E B welding is carried out in a vacuum with no filler material. Parent metal is re-melted in vacuum to produce the weld. The process is now fully programmed to ensure consistency

- Weld speed; EBW can weld thick sections 100 times faster than conventional processes.

- Welding of dissimilar metals; enables combinations of materials for best cost or performance

- Minimal distortion, parts as accurate as finish ground gears can be welded.

What is the difference between EB and Laser welding?

Both high energy density processes. EB welding produces the deepest high-quality welds, but the size of the vacuum chamber limits the size of assemblies and evacuation slows of speed of overall weld cycle time.

Laser uses highly focused light does not need a vacuum, but still needs controlled atmosphere to weld high strength materials. It is very successful for low power, high speed welds for electronic and thin metal joining, where fibre optics can be used to deliver the light source.

Our Precision TIG Welding services include:

- Mechanised, manual and fully programmed welding equipment

- Qualified and externally assessed welding staff

- Approvals; NADCAP, AS9100 & 9104, ASME IX , see Quality Approvals

- Programmable Integrated wire feed equipment

- 1.5 M Argon glove chamber.

- Full NDT support including X-ray, FPI, Vacuum, and Pressure leak testing.

- Macro & Micro weld reports including Hardness testing.

- Heat Treatment for pre and post weld processing.

- Industrial Membership of TWI (The Welding Institute) for expert support and advice.