Our non-destructive testing services include:

- Radiography, including CR digital film system

- Fluorescent Dye Flaw detection

- Vacuum & Air leak testing

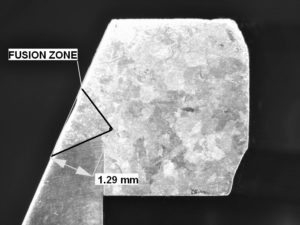

- Material evaluation, macro, Hardness testing

- Micro to x 500 magnification

Staff approved to:

- EN4179 (Aerospace)

- EN473/ISO9712 (Industrial)

- SNT-TC-1A (Oil & Gas)

- PCN (Personal)

Consultancy agreements with external specialists

Industrial membership TWI (The Welding Institute) and BINDT

We have approvals from:

- AS9100 Rev D.

- NADCAP

- Rolls-Royce classified parts UK & Germany

- Rolls-Royce Nuclear Submarines

- G E Aircraft Engines (USA)

- BAe Systems

- Airbus

- Meggitt Aerospace Group

- Leonardo

- UTC

- Eaton Aerospace

- FR/Cobham Group

- Curtis-Wright

- Safran

- Lufthansa Technik

- ITP Spain & UK

- Schlumberger Oilfield Technology